Membrane Bioreactor (MBR)

Membrane bioreactor (MBR) is a biological waste-water ultra filtration treatment system which is used to remove organic matter and is used to separate solids from the liquid, generating a bio sludge. Proving to be the most economic, and effective system for waste water treatment.

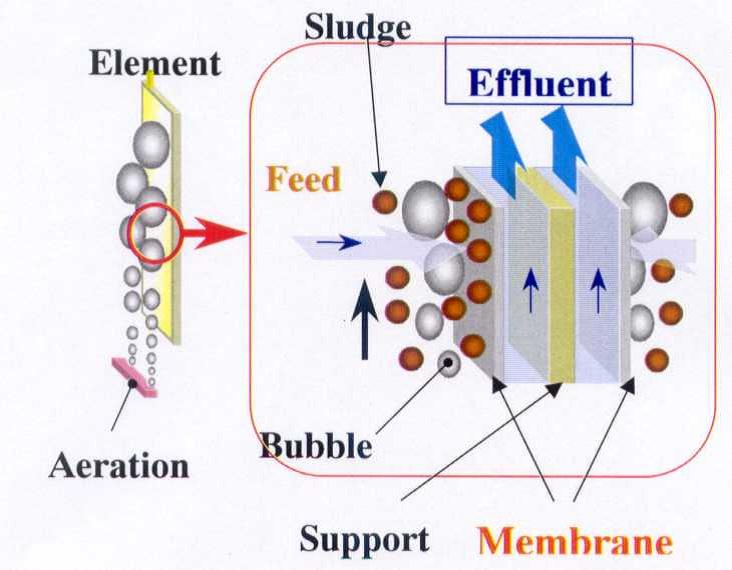

Activated sludge in the aeration tank is clearly removed by the flat sheet type submerged membrane. The membrane module consists of housing, aeration diffuser, permeate water manifold and membrane elements. The membrane element consisting of flat sheet membranes sandwiching a support panel is set up vertically. Feed water including activated sludge is filtrated by flat sheet membranes with pore size of 0.02 micron meter. The air bubbles supplied from the bottom of the membrane elements continuously scour off cake of activated sludge accumulated on the membrane surface. This is continuous filtration operation. The air bubbles are also used for the biological reaction to decompose organic substances included in the raw sewage.

The material of the membrane is hollow fiber PVDF (polyvinylidene difluoride). PVDF is fluorine polymer which has high stability for chemicals and good physical strength. The form of membrane is fiber reinforced flat sheet membrane. The membrane has small and uniform pore size. Therefore, the rejection property of this membrane is excellent. Almost all particles with sizes more than 0.1 micron meter can be removed effectively using this membrane.

Description of Treatment Scheme

Sewage effluent shall be collected into a screen chamber. This manually cleaned screen is provided to remove floating and big size particles which may otherwise choke the pumps and pipe lines.

After screening, sewage effluent is collected in underground equalization tank where mixing of effluent is done through air diffusion system. From equalization tank, Non clog, submersible pumps transfer the effluent to Biological chamber for further degradation of organic impurities.

In Biological-MBR tank, high MLSS (mixed liquor suspended solids) i.e. up to 8000 mg/l is maintained. The high amount of bacteria gives better and complete removal of organic matter from the raw sewage effluent in relatively small area. Oxygen required for the bacteria is supplied through the twin lobe type air blower. The air is used both for scouring of membranes and supplying oxygen to bacteria. The filtration is carried out by the suction pump directly sucking permeated water from PMTR modules at vacuum. The permeate water produced is ultra filtered and having turbidity < 1.0 NTU.

ADVANTAGES OF MBR

MBR is the latest technology in sewage and wastewater treatment with many advantages as listed below:

Operation

MBR technology is a Fully Automatic System, thus, resulting in Less maintenance and man power required. Auto Cleaning and Backwashing of MBR is done automatically at regular intervals resulting in higher membrane life, consistent output quality and no operation difficulties.

Gives superior quality of treated water

The quality of treated water in case of MBR is much superior than conventional biological systems. As the membrane acts as a physical barrier, it does not allow any sludge particles and to great extent bacteria and viruses to pass through it. Microorganisms like coliform or cryptosporidium can be easily removed in MBR.

Does not require clarifier / Settler unit

MBR does not require clarifier tank where as conventional activated sludge process requires clarifier which further adds to the area requirement and cost.

Do not require further tertiary treatment

Conventional biological systems require further tertiary treatment to match the performance of the MBR system.

Less number of treatment units

MBR system has minimum number of treatment units and very simple to operate. It does not require any regular handling of hazardous chemicals. As the treatment units are less, it is less prone to system breakdowns.

High membrane life

The membranes are made of PVDF with PET non woven fabric. It is resistant to many chemicals and hence has long operational life.

Retrievable membranes

The membranes can be easily taken out of the system for physical inspection without emptying the aeration tank which makes the operation and maintenance of the unit simple.

Low Sludge Production

The sludge produced is only one fourth of conventional system. The sludge produced is also high stable and hence easy to dispose off.

Explain the Working Principle of Membrane Bioreactor

Membrane Bioreactor is the combination of a membrane process like ultrafiltration with the activated sludge process. The Membrane Bioreactor was developed commercially by Dorr-Oliver in 1960. It is used for the ultrafiltration and Microfiltration. It is mainly used in Sewage Water Treatment and Effluent treatment Plant.

Working Principle of Membrane Bioreactor

First of all the sewage waste and industrial effluent enter in the stilling chamber then transfer towards the screen chamber. There are some specially designed by Hyper Filteration which is used in this chamber to remove the plastic, coarse particles ,metals etc. form the water to prevent the equipment for further process and these tools also used to protect the passing away of the pipes for the water this process or treatment is known as elimonry treatment in the water treatment process. After completing the process of elimonry process the sewage waste and effluent move to equalization tank. Equalization tank is used for maintaining the constant and uniform rate of sewage and effluent mixture. It is also used to convert sewage and Effluent mixture in to homogeneous. Due to aeration in the equalization tank, the velocity of detonation has been decreased of wastewater from 10% to 20%. Blowers are used in MBR tank and Equalization tank. After the equalization of the homogeneous raw sewage and industrial effluent send to the Membrane Bioreactor. Membrane Bioreactor is part of secondary or primary Biological treatment. Membrane Bioreactor has an aeration system like Activated sludge tank. In the Membrane Bioreactor, the aeration system is used constantly to provide continuous circulation to the sewage to maintain the level of the dissolved oxygen in the chamber. A microorganism which is also known as biolayer has created a layer of the plastic media and with the help of proper aeration, the microorganism can be increased through that the efficiency of Membrane Bioreactor can be increased sententiously.